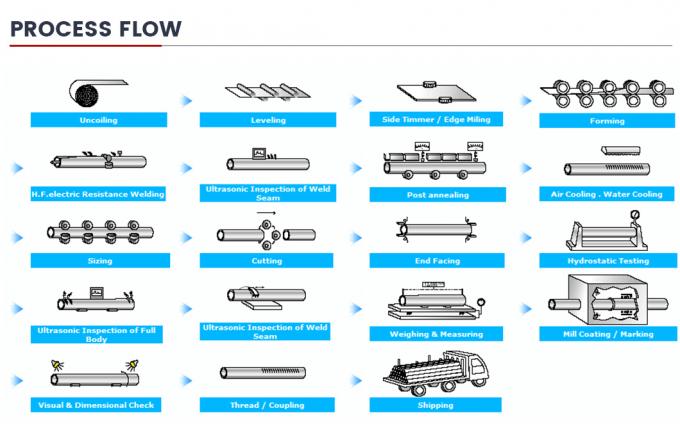

Zhengde Welded steel pipe, also known as welded pipe, is a steel pipe made by welding steel plates or strips after being rolled and formed. Welded steel pipes are divided into straight seam welded pipes and spiral welded pipes according to the form of welds. Classified by production method: arc welded pipe, resistance welded pipe, (high-frequency, low-frequency) gas welded pipe, furnace welded pipe. The production process of straight seam welded pipe is simple, with high production efficiency, low cost, and rapid development. The strength of spiral welded pipes is generally higher than that of straight seam welded pipes. Narrow billets can be used to produce larger diameter welded pipes, and billets of the same width can also be used to produce welded pipes of different diameters. However, compared to straight seam pipes of the same length, the weld length increases by 30-100% and the production speed is lower. Thick wall coil products include: large coil, large diameter thick wall coil, various materials thick wall coil, hot rolled thick wall coil, cold rolled thick wall coil, etc.

Zhengde Welded steel pipe, also known as welded pipe, is a steel pipe made by welding steel plates or strips after being rolled and formed. Welded steel pipes are divided into straight seam welded pipes and spiral welded pipes according to the form of welds. Classified by production method: arc welded pipe, resistance welded pipe, (high-frequency, low-frequency) gas welded pipe, furnace welded pipe. The production process of straight seam welded pipe is simple, with high production efficiency, low cost, and rapid development. The strength of spiral welded pipes is generally higher than that of straight seam welded pipes. Narrow billets can be used to produce larger diameter welded pipes, and billets of the same width can also be used to produce welded pipes of different diameters. However, compared to straight seam pipes of the same length, the weld length increases by 30-100% and the production speed is lower. Thick wall coil products include: large coil, large diameter thick wall coil, various materials thick wall coil, hot rolled thick wall coil, cold rolled thick wall coil, etc.

All welded pipes can be made into galvanized welded pipes, which can be found through product consultation on the homepage.

| DN | Welded steel pipe (ordinary) | Welded steel pipe (thickened) | Seamless steel pipe (hot rolled) | Spiral welded steel pipe | ||||

| pg≤1.0Mpa | pg≤1.6Mpa | pg≤2.5Mpa | pg≤1.6Mpa | |||||

| D×∮ | (Kg/m) | D×∮ | (Kg/m) | D×∮ | (Kg/m) | D×∮ | (Kg/m) | |

| DN15 | 21.3*2.75 | 1.25 | 21.3*3.25 | 1.44 | ---- | ---- | ---- | ---- |

| DN20 | 26.8*2.75 | 1.63 | 26.8*3.5 | 2.01 | ---- | ---- | ---- | ---- |

| DN25 | 33.5*3.25 | 2.42 | 33.5*4 | 2.91 | 32*3.5 | 2.46 | ---- | ---- |

| DN32 | 42.3*3.25 | 3.13 | 42.3*4 | 3.77 | 38*3.5 | 2.98 | ---- | ---- |

| DN40 | 48*3.5 | 3.84 | 48*4.25 | 4.58 | 45*3.5 | 3.58 | ---- | ---- |

| DN50 | 60*3.5 | 4.88 | 60*4.5 | 6.16 | 57*3.5 | 4.62 | ---- | ---- |

| DN65 | 75.5*3.75 | 6.64 | 75.5*4.5 | 7.88 | 73*4 | 6.81 | ---- | ---- |

| DN80 | 88.5*4 | 8.34 | 88.5*4.75 | 9.81 | 89*4 | 8.38 | ---- | ---- |

| DN100 | 114*4 | 10.85 | 114*5 | 13.44 | 108*4 | 10.26 | ---- | ---- |

| DN125 | 140*4.5 | 15.04 | 140*4.5 | 18.24 | 133*4 | 12.72 | ---- | ---- |

| DN150 | 165*4.5 | 17.81 | 165*5.5 | 21.63 | 159*4.5 | 17.14 | 168*5 | 20.1 |

| DN200 | ---- | ---- | ---- | ---- | 219*6 | 31.52 | 219*5 | 31.52 |

| DN250 | ---- | ---- | ---- | ---- | 273*8 | 52.28 | 273*7 | 45.92 |

| DN300 | ---- | ---- | ---- | ---- | 325*8 | 62.54 | 325*7 | 54.9 |

| DN350 | ---- | ---- | ---- | ---- | 377*9 | 81.67 | 377*7 | 63.87 |

| DN400 | ---- | ---- | ---- | ---- | 426*9 | 92.55 | 426*7 | 72.33 |

| DN450 | ---- | ---- | ---- | ---- | 480*9 | 104.53 | 478*7 | 81.31 |

| DN500 | ---- | ---- | ---- | ---- | 530*9 | 115.62 | 529*7 | 90.11 |

| DN600 | ---- | ---- | ---- | ---- | 630*9 | 137.82 | 630*7 | 107.5 |

Quality first: production and inspection in strict accordance with production standards;

Price advantage: discounts based on real market prices;

Transaction security: There will be no loss of customer funds;

After-sales guarantee: the customer's problem is our problem;

Long-term cooperation: quality assurance, price advantage, sincere service can last for a long time.

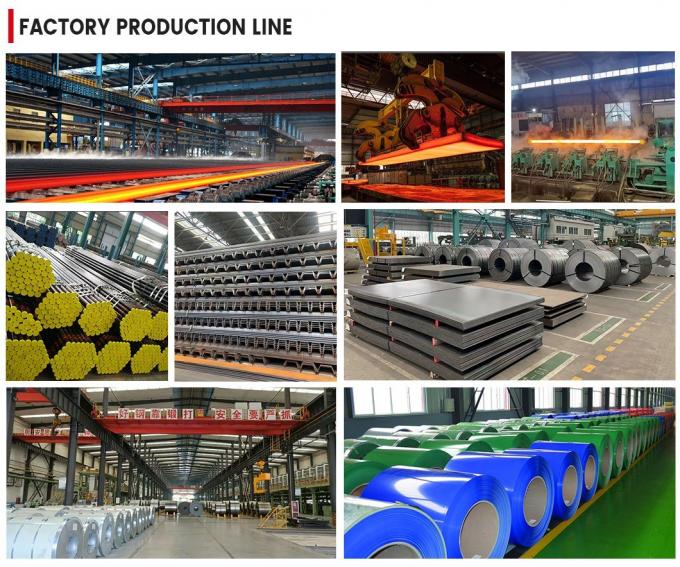

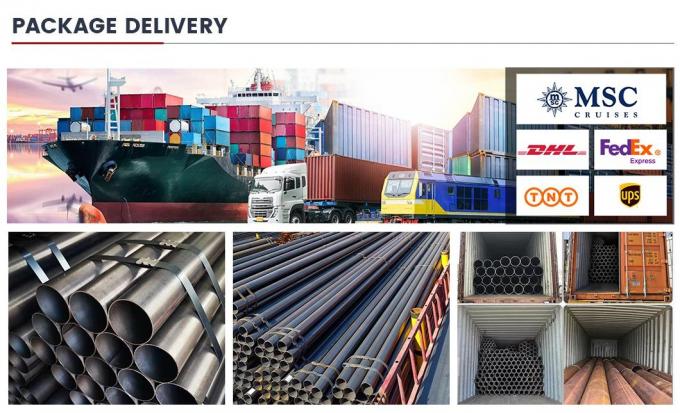

Shandong Zhengde Metal Manufacturing Co., Ltd. is a production and sales company integrating hot-rolled steel coils, cold-rolled steel coils, galvanized steel coils, color-coated steel coils, section steel, steel pipes, steel wires, metal mesh, stainless steel, aluminum, copper and other metal products integrated large enterprises. Five production and sales bases have been formed in Binzhou, Liaocheng, Wuxi, Tianjin, Jinan and Tai'an, with more than 100 production lines, 4 nationally recognized laboratories, 2 technical engineering centers, and 5 enterprise technology centers. Products are exported to more than 50 countries and regions such as North America, South America, Europe, Africa, Oceania, Middle East, and Southeast Asia.

Shandong Zhengde Metal Manufacturing Co., Ltd. is a production and sales company integrating hot-rolled steel coils, cold-rolled steel coils, galvanized steel coils, color-coated steel coils, section steel, steel pipes, steel wires, metal mesh, stainless steel, aluminum, copper and other metal products integrated large enterprises. Five production and sales bases have been formed in Binzhou, Liaocheng, Wuxi, Tianjin, Jinan and Tai'an, with more than 100 production lines, 4 nationally recognized laboratories, 2 technical engineering centers, and 5 enterprise technology centers. Products are exported to more than 50 countries and regions such as North America, South America, Europe, Africa, Oceania, Middle East, and Southeast Asia.